When it pertains to sealing and isolating elements in diverse commercial setups, the rubber service plug from DLYY exemplifies an unified blend of resilience, dependability, and development. Rubber plugs have ended up being vital tools in lots of sectors, serving essential roles in markets varying from automotive to hydraulics, plumbing to pneumatics, and everything in between. The trick to their considerable applicability hinges on the unique residential properties of rubber, coupled with precise workmanship and design prowess that DLYY brings to the table. Rubber, as a product, boasts phenomenal elasticity, insulation, and resistance to different ecological factors such as extreme temperatures, deterioration, and abrasion-- qualities that are tremendously beneficial in extreme commercial settings. DLYY scrupulously leverages these inherent residential properties of rubber to provide to a myriad of commercial demands, thereby ensuring that every plug manufactured is not just a tool yet a reputable ally in facility and demanding jobs.

The main function of rubber service connects is to produce a limited seal to protect against leaks and contamination, a typically undervalued but essential element of preserving system integrity and functional performance. The versatility of rubber service connects to various sizes and shapes of hoses and pipelines likewise enhances their energy, making them a flexible component in numerous setups.

DLYY's know-how in manufacturing high-quality rubber items is underscored by strenuous top quality control and a deep understanding of commercial dynamics. Each plug is crafted to endure mechanical stress and strenuous usage, personifying durability that assures clients their systems are secured for the long haul. DLYY includes modern production technologies and methods to enhance the performance and effectiveness of their rubber plugs. This consists of careful choice of rubber blends to make certain the suitable solidity, tensile strength, and thermal stability that fulfill or go beyond sector requirements. By maximizing the mix and design of their rubber service plugs, DLYY is able to use bespoke remedies that are finely tuned to particular client needs, whether it involves resistance to chemical exposure or viability for high-pressure applications.

The significance of a well-engineered rubber plug extends beyond the immediate useful advantages; it works as a testament to the improvements in product scientific research and industrial advancement. DLYY goes to the leading edge of equating these developments into tangible benefits for their clients. For instance, the intro of ingredients to improve UV and ozone resistance in their rubber compounds mirrors an understanding of real-world ecological obstacles dealt with by markets. In addition, advancements such as enhanced ergonomic designs ensure convenience of setup and removal, softening the labor demands on employees and minimizing the risk of damage throughout application. This thoughtful interest to detail not just celebrates the functionality of rubber plugs yet likewise highlights DLYY's dedication to improving user experience and functional security.

In the more comprehensive landscape of industrial products, the role of rubber solution plugs as champions of functional efficiency and safety and security can not be overstated. They are unrecognized heroes that help stop costly downtime, devices damage, and unsafe events. The flexibility of rubber plugs is witnessed in their capability to change perfectly throughout applications-- whether made use of during devices upkeep, in assembly lines, or as a momentary safety measure during transportation and storage space. DLYY's method to high quality and consumer satisfaction sees them continuously improving their product offerings and broadening their profile to satisfy arising commercial demands, guaranteeing customers constantly have accessibility to state-of-the-art services that keep their operations running efficiently and safely.

Additionally, in an age where sustainability and eco-efficiency are much more than just buzzwords, DLYY sets a benchmark by embracing eco pleasant procedures in the manufacture of their rubber plugs. This not only involves using recyclable products anywhere possible but additionally applying energy-efficient practices in production facilities. As firms aim to line up with global sustainability objectives, picking items from producers like DLYY who prioritize eco-friendly methods becomes progressively important, enhancing initiatives to minimize the carbon footprint while maintaining functional performance.

The key feature of rubber service connects is to develop a limited seal to protect against leakages and contamination, a frequently ignored but essential aspect of maintaining system honesty and functional performance. The versatility of rubber service plugs to various sizes and shapes of hoses and pipelines additionally improves their utility, making them a versatile part in numerous setups.

DLYY's expertise in producing premium rubber products is underscored by strenuous high quality control and a deep understanding of industrial characteristics. Each plug is crafted to stand up to mechanical anxiety and rigorous use, symbolizing longevity that ensures customers their systems are secured for the lengthy haul. DLYY integrates modern-day production technologies and techniques to boost the performance and effectiveness of their rubber plugs. This includes cautious option of rubber blends to make sure the appropriate firmness, tensile toughness, and thermal stability that go beyond or meet market requirements. By maximizing the blend and design of their rubber rubber plug service plugs, DLYY is able to supply bespoke services that are carefully tuned to specific client needs, whether it involves resistance to chemical exposure or viability for high-pressure applications.

In recap, rubber solution connects from DLYY stand for the peak of top quality and performance in commercial rubber products. Their role in allowing seamless operations with powerful securing capability, resistance to the elements, and resilient building highlights their worth recommendation as a commercial need. The firm's detailed focus to layout and an aggressive position in the direction of ecological and technological improvements strengthen their setting as a leading supplier in the world of industrial rubber services. Whether dealing with elaborate needs of sectors like automotive repair, chemical handling, or building and construction, DLYY's rubber solution connects show important in securing functional stability, making sure a mutually useful connection with market clients by guarding their facilities with efficient and trusted options. For any sector expert tasked with optimizing and keeping system performance, relying on DLYY's rubber service connects is not just a choice-- it's a testimony to focusing on sustainability, top quality, and dependability.

Jason J. Richter Then & Now!

Jason J. Richter Then & Now! Ross Bagley Then & Now!

Ross Bagley Then & Now! Ashley Johnson Then & Now!

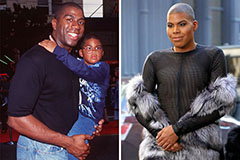

Ashley Johnson Then & Now! Earvin Johnson III Then & Now!

Earvin Johnson III Then & Now! Morgan Fairchild Then & Now!

Morgan Fairchild Then & Now!